详细内容:

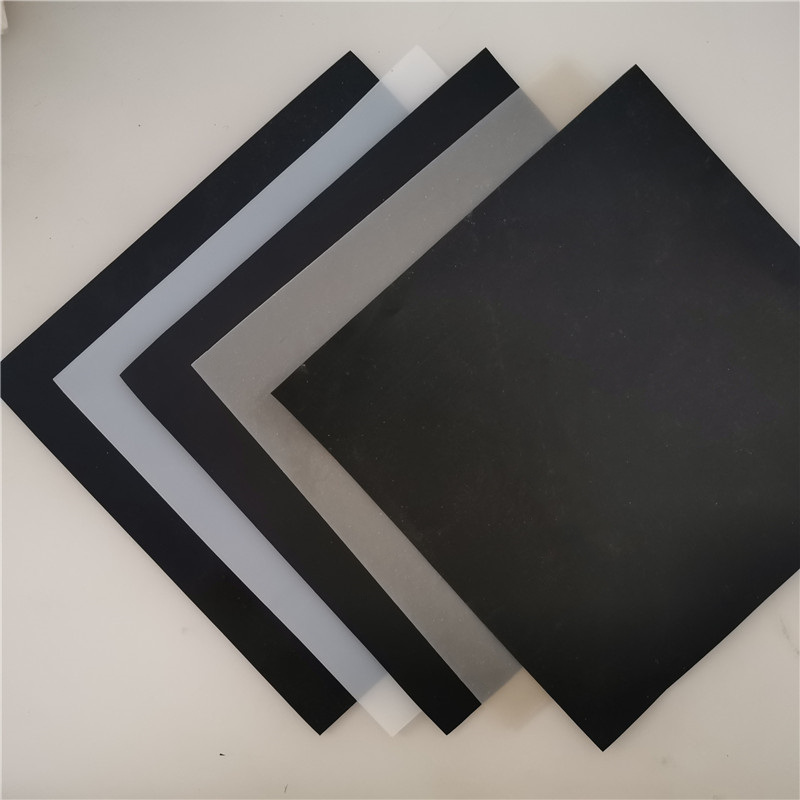

Geomembrane is widely used in landfill sites, road and bridge projects, tunnels and culverts, landscape gardening, greening

projects, sewage treatment and other fields. Traditional geomembrane, due to its smooth surface, has weaknesses in practical

application, such as low friction coefficient, easy sliding in contact with the soil layer, and insufficient stability during use,

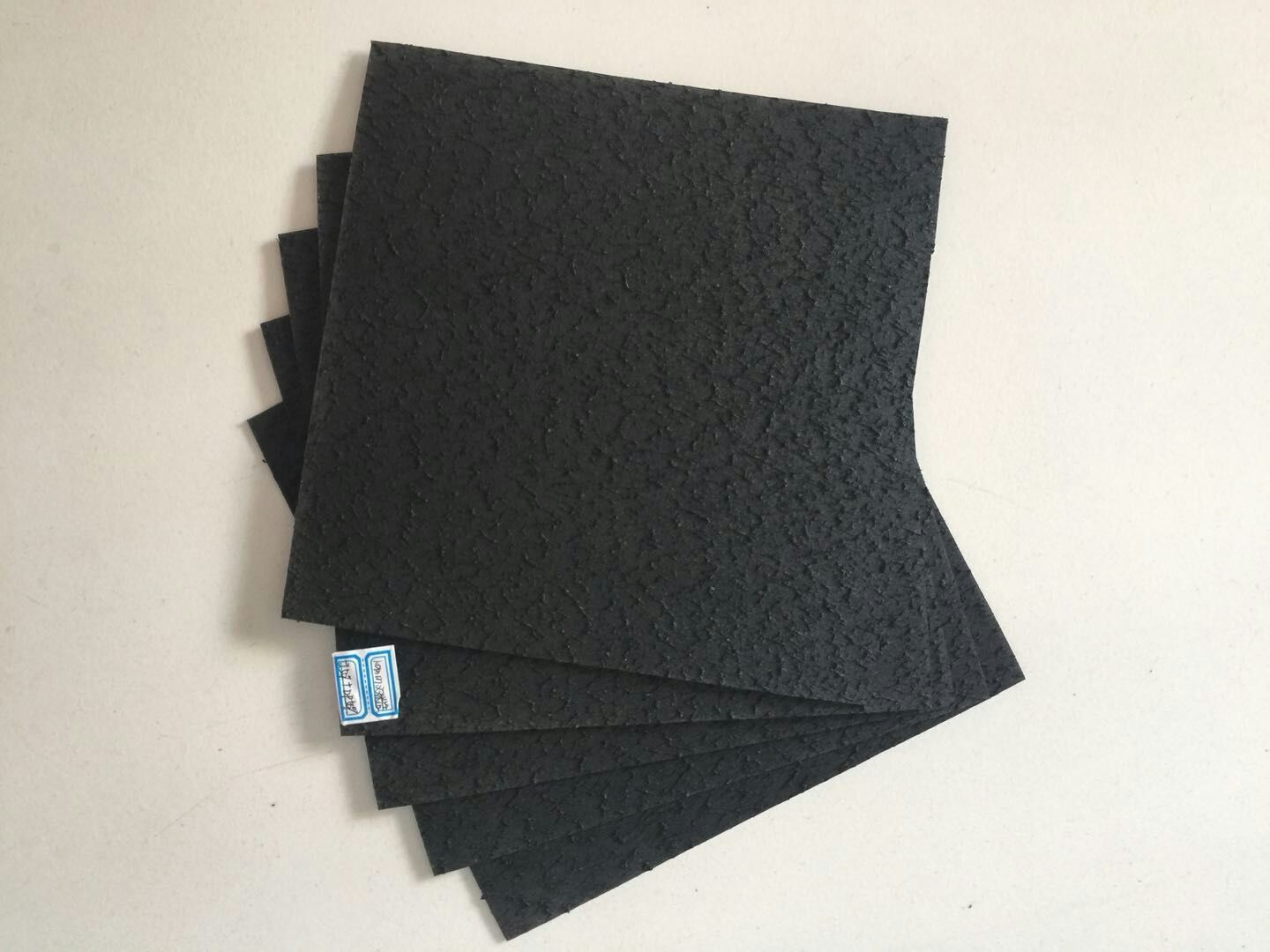

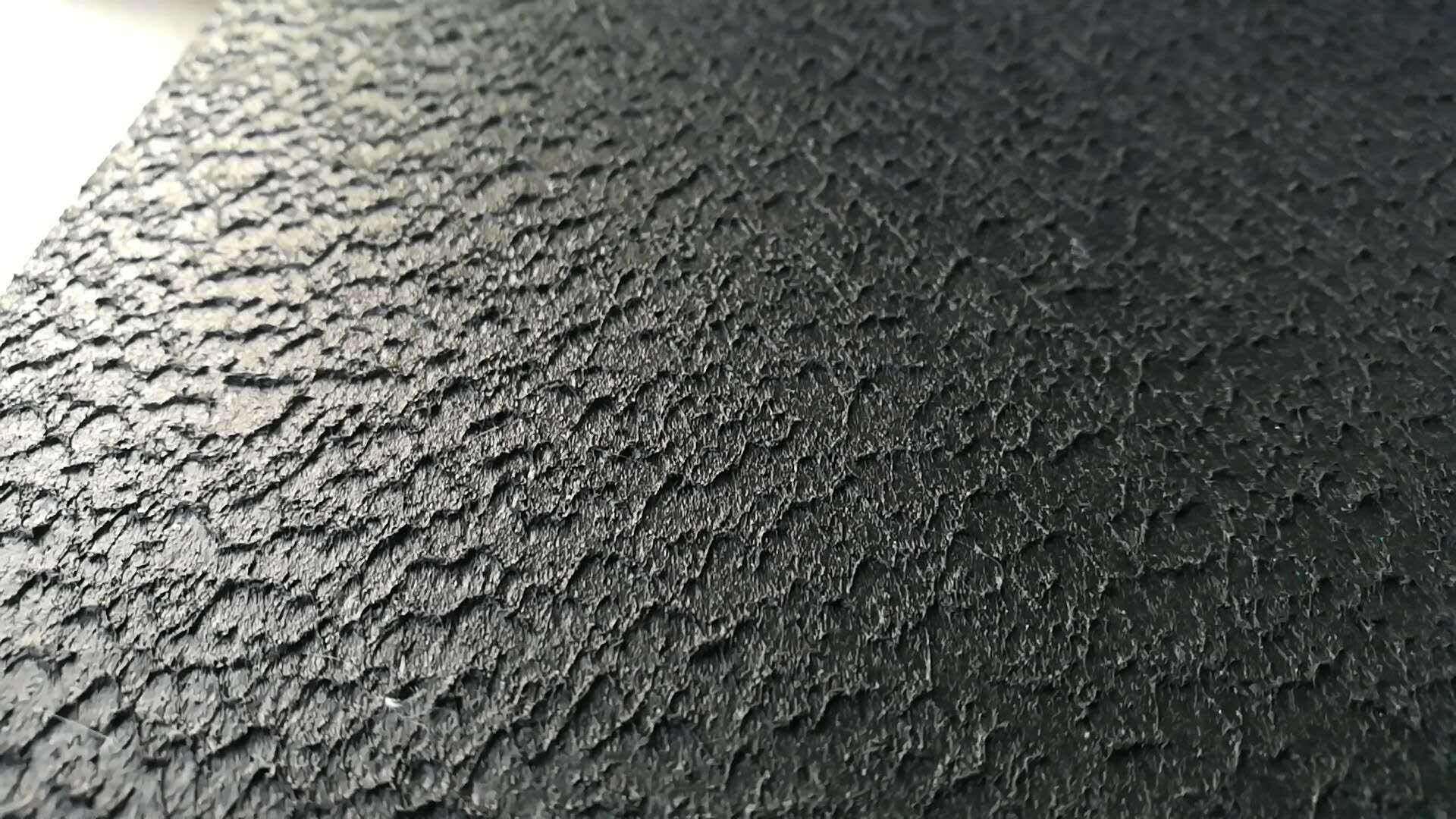

especially in the construction and use of slopes The rough surface geomembrane has completely solved this problem due

to its rough surface. The main forming processes of rough surface geotextile membranes include: spinning roughening method,

embossing roughening method, chemical foaming roughening method and nitrogen roughening method, etc.

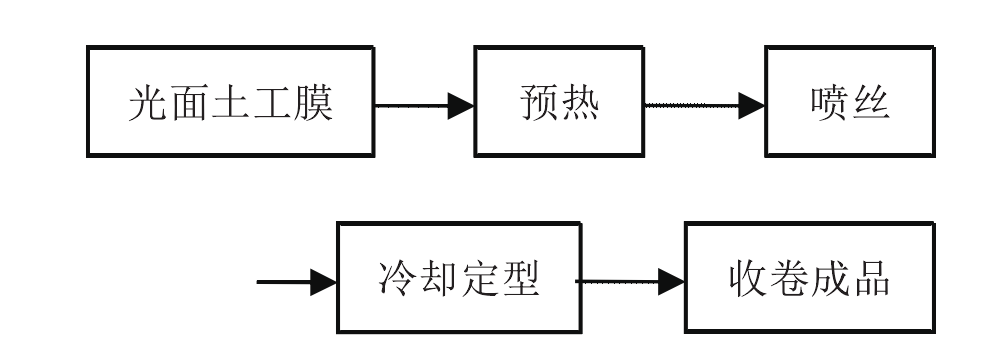

The spinning roughening method involves preheating the PE smooth surface geomembrane to make the surface layer of the

geomembrane to be roughened reach above the heat distortion temperature. Then, through a special powder coating device,

molten plastic filaments are sprayed onto the surface to be roughened. After cooling, a rough surface layer is obtained. The

spinneret roughening process is complex. The key technologies lie in the control of the roughened surface of the geomembrane,

the manufacturing and spraying of plastic filaments, and the selection of materials for and rough layers of filaments. The spinning

process is difficult, the rough surface quality is unstable, and the plastic filaments are prone to fall off the surface the geomembrane,

thereby reducing its anti-slip performance. The spinnerization and roughening method belongs to secondary molding, which

involves further processing and shaping the smoothed surface geomembrane. The smoothed surface geomembrane produced

by calendering and blow molding processes can be preheated and spinnerized to obtain PE rough surface geomembrane.

Alternatively, the preheating and spinnerization processes can be directly added to the geomembrane production line to

achieve continuous production of PE rough surface geomembrane.

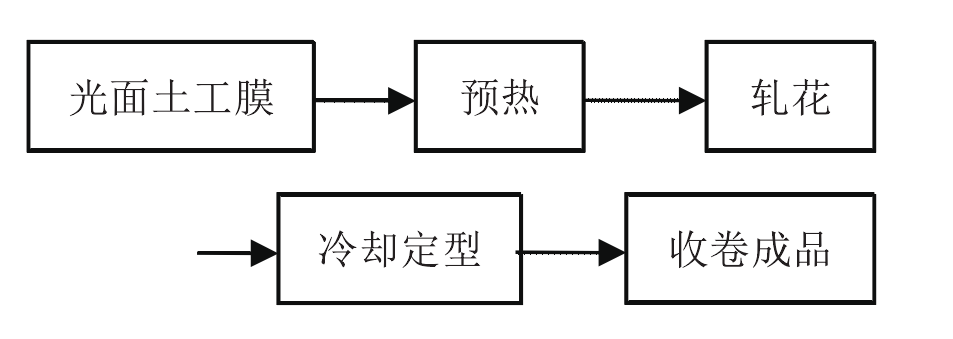

The rough-surfaced geotextile membrane is formed by preheating the PE smooth surface geotextile membrane through a rough-surfaced geotextile membrane roller and then cooling it to form a rough-surfaced geotextile membrane. The embossing roughening method, like the spinneret roughening method, belongs to secondary forming. It involves preheating and embossing the smooth-surfaced geotextile membrane to obtain PE rough-surfaced geotextile membrane. The preheating and embossing processes can also be directly added to the geotextile membrane production line to achieve continuous production of PE rough-surfaced geotextile membrane.

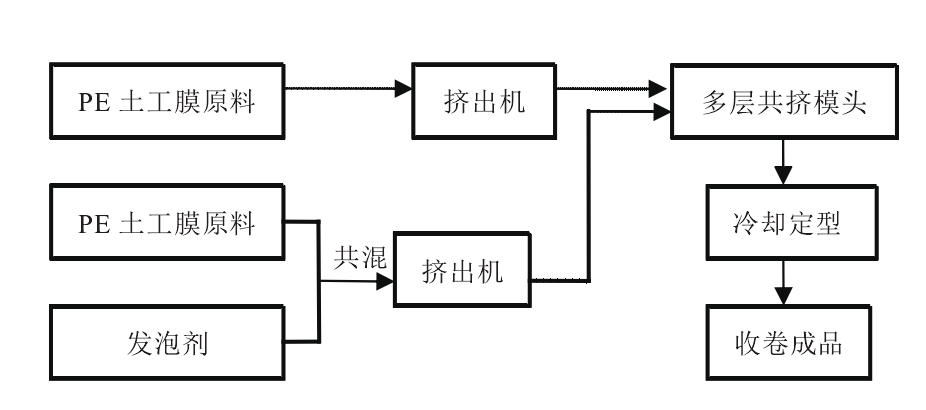

The chemical foaming roughening method is a technique that uses foaming agents to make the surface of geomembranes rough. Chemical foaming agents are added to the raw materials of the geotextile membrane that need to be roughened. The extrusion molding die head for the rough-surfaced geotextile membrane is a multi-layer co-extrusion die head. The foaming agent of the rough-surfaced layer, the blend of the PE geotextile membrane raw materials, and the raw materials of the ordinary layer of PE geotextile membrane enter different flow channels of the multi-layer co-extrusion die head together to achieve simultaneous extrusion. During the extrusion process, the rough surface layer, due to the presence of foaming agents, will form uneven rough protrusions at the moment the melt exits the die head because of the generation of bubbles, thus creating a rough surface.

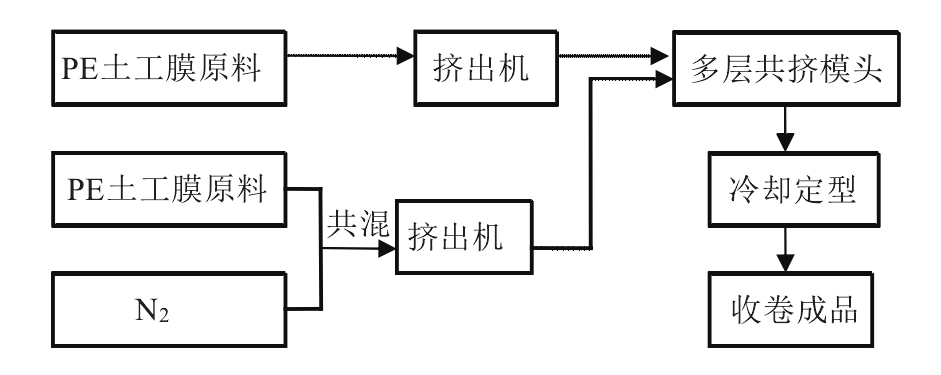

The nitrogen roughening method is similar to the foaming roughening method. The rough surface layer is made by replacing the foaming agent with nitrogen and directly blending it with the raw materials of PE geomembrane. After blending, it enters different flow channels of the multi-layer co-extrusion die head together with the raw materials of the ordinary layer PE geomembrane and is co-extruded and formed. The nitrogen roughening method, like the chemical foaming roughening method, is a one-time molding process and can be used for the continuous production of PE rough-surfaced geotextile membranes in the blow molding process.