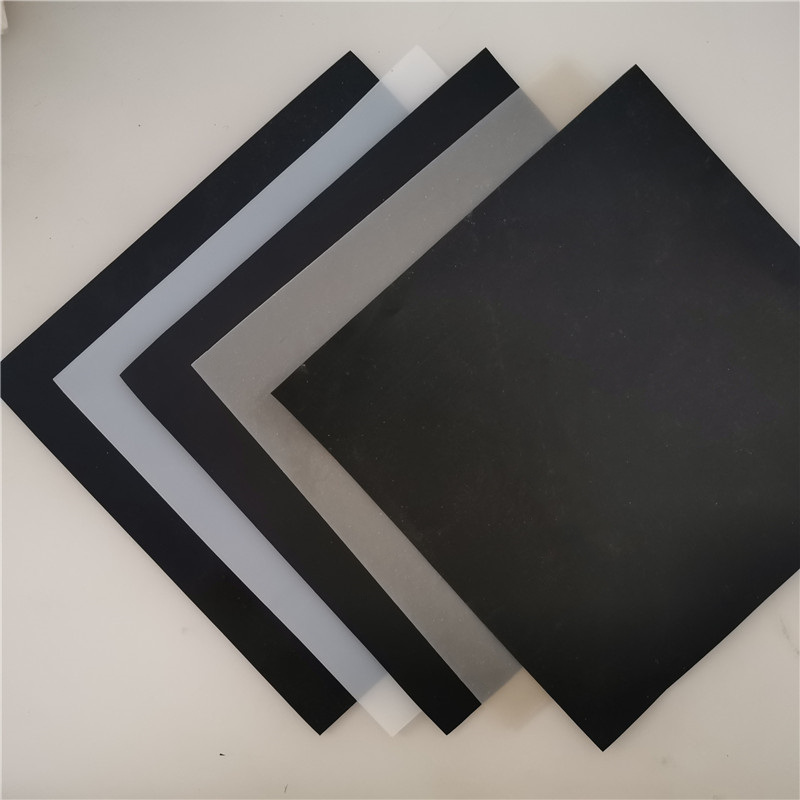

产品介绍:

![1602836707605898.jpg 1-200G0143Z9506[1].jpg](/static/upload/image/20201016/1602836707605898.jpg)

In recent years, the number of anti-seepage membrane projects has increased rapidly, especially

the application of anti-seepage membranes in embankment anti-seepage has increased more signif-

icantly. The success or failure of anti-seepage membrane projects mainly depends on the construction

process, and the quality of the anti-seepage membrane construction technology directly affects the

construction quality of the anti-seepage membrane.

The welding methods of anti-seepage membranes include electric heating wedges, hot melt

extrusion, high-temperature gas welding, etc. Among them, electric wedge welding is widely applied.

Some scholars have conducted relatively in-depth research on the hot wedge welding process

For a certain model of hot wedge welding machine and a certain type and thickness of anti-

seepage membrane, the selection of welding parameters such as hot wedge temperature, welding

speed, and roller pressure is also affected by local atmospheric temperature and wind force. Domestic

research on welding process technology has not yet reached a systematic and in-depth level and is

still at the empirical stage for various projects.

When summarizing the splicing process of anti-seepage membranes, it is necessary to avoid

filling in the gaps as much as possible, especially for the welding process, to minimize missed welds,

false welds, and multiple pause points in a single weld seam. Although these defects were found to

be reweldable, the welding quality of the hand-held welding torch was far inferior to that of the

welding machine.