产品介绍:

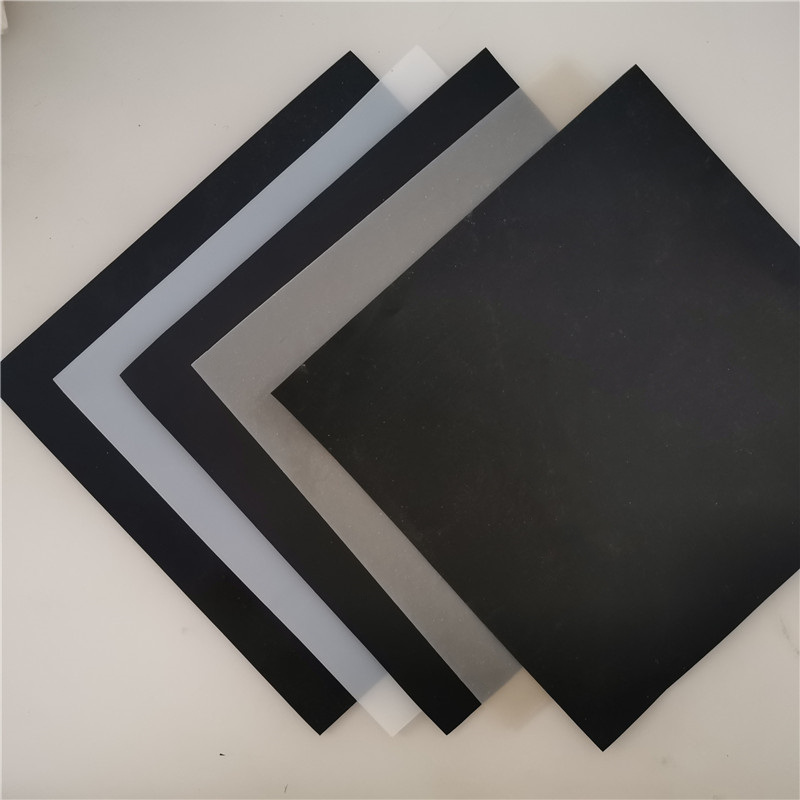

Product Introduction: Bentonite waterproof blanket (GCL) is a new type of geosynthetic material. It is a blanket-like

material made by needling sodium-based bentonite particles wrapped in two layers of geotextile. Due to the expansion

of bentonite upon contact with water and the formation of hydration, a new impermeable composite material is formed.

It is a new type of anti-seepage and isolation material. At present, there are two commonly used products according to

engineering needs: One is called needle-punched sodium-based bentonite waterproof blanket, which is made by wrapping

bentonite with a layer of non-woven fabric and a layer of split film filament woven fabric (commonly known as woven fabric).

This product can disinfect, prevent seepage and isolate toxic substances. When in use, if it is used in combination with a

waterproof board, it will achieve a better anti-seepage effect. Another type is called the needle-punched coated sodium-

based bentonite waterproof blanket. It involves coating a layer of polyethylene film on the non-woven fabric surface of the

needle-punched sodium-based bentonite waterproof blanket, with a film thickness of 0.3mm to 1.5mm. This product not

only provides sufficient anti-seepage and permanent waterproofing but also avoids the repeated construction of geotextile

membranes, improving construction efficiency and reducing construction costs. The specific film thickness can be determined

according to the engineering requirements.

Waterproofing mechanism

When bentonite particles come into contact with water, they expand, forming a uniform colloidal system. Under the restrictive

effect of two layers of geotextiles, the bentonite expands from disorder to order. The continuous water absorption and expansion

result in the bentonite layer itself becoming dense, thereby having a waterproof effect.

Anti-seepage principle

The mineralogical name of bentonite is montmorillonite. Bentonite is mainly classified into two categories based on chemical

composition: sodium-based and calcium-based. Bentonite has the property of swelling upon contact with water. When calcium-

based bentonite swells, its expansion is only about three times its own volume. However, when sodium-based bentonite comes

into contact with water, it adsorbs five times its own weight of water and swells to more than 15 to 17 times its original volume.

Locking sodium-based bentonite between two layers of geosynthetic materials plays a protective and reinforcing role, endowing

GCL with its overall shear strength.

Features

1. Compactness: Under water pressure, sodium-based bentonite forms a high-density diaphragm. When its thickness is about

3mm, its water permeability is below 5×10 ⁻ 11m/s, which is equivalent to 100 times the compactness of 30cm thick clay, and

it has a strong self-water retention performance.

2. Waterproof performance: As sodium-based bentonite is an inorganic material, it will not age or corrode even after a long

time or when the surrounding environment changes, thus ensuring long-lasting waterproof performance.

3. Easy construction: Compared with other waterproof materials, the construction is relatively simple and does not require

heating or pasting. Just connect and fix it with bentonite powder and nails, washers, etc. No special inspection is required

after construction. If any waterproofing defects are found, they are also easy to repair. GCL is the waterproofing material

with the shortest construction period among the existing ones.

4. Not affected by temperature: It will not break brittle even in cold climates.

5. Integration of waterproof materials and objects: When sodium-based bentonite comes into contact with water, it has an

expansion capacity of 20 to 28 times. Even if the concrete structure experiences vibration and settlement, the bentonite

within the GCL can repair cracks on the concrete surface within 2mm.

6. Green and environmentally friendly: Bentonite is an inorganic material and has no particular impact on the environment,

featuring excellent environmental protection performance.

7. It has a high performance-to-price ratio and a very wide range of applications. The product width can reach up to 6

meters, greatly enhancing the construction efficiency.

Applicable environment

1. Anti-seepage for municipal engineering, subways, underground works of buildings and rooftop water storage tanks.

2. Environmental protection and sanitation, domestic waste landfill, sewage treatment plant, industrial waste.

3. Water conservancy, anti-seepage, leakage plugging and reinforcement of DAMS in rivers, lakes and reservoirs.

4. Anti-seepage of ponds in artificial lakes and golf courses in gardens, etc.

5. Anti-seepage, anti-corrosion, leakage prevention and reinforcement for projects in fields such as petrochemicals,

mining and agriculture.