产品介绍:

![1602666720207176.jpg 1-20031Q42114[1].jpg](/static/upload/image/20201014/1602666720207176.jpg)

Product Introduction

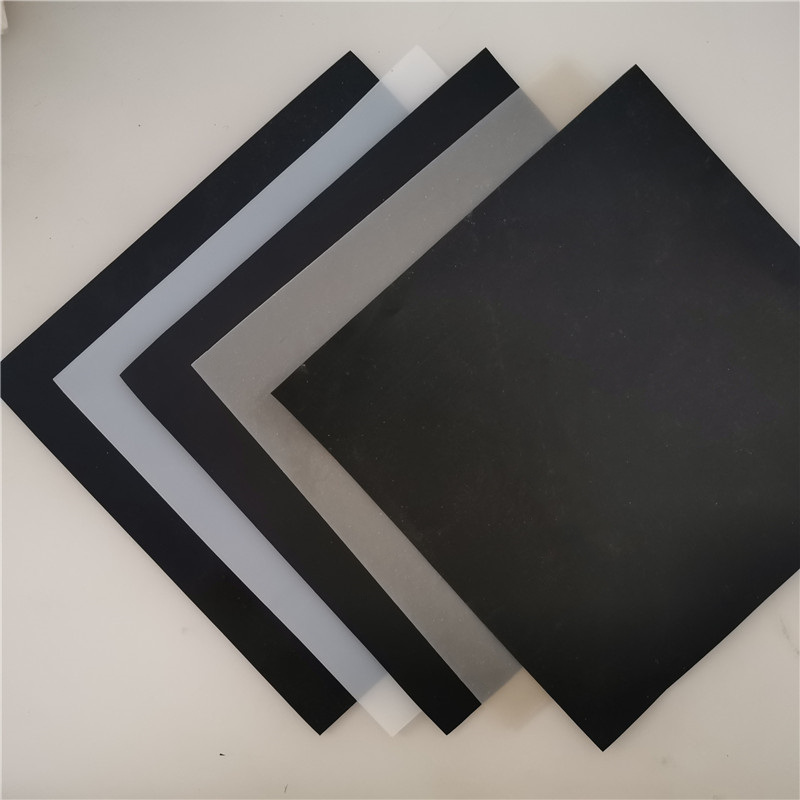

Bentonite waterproof blanket is a kind of geosynthetic material specially used for preventing seepage in artificial

lake water features, landfill sites, underground garages, rooftop gardens, water tanks, oil depots and chemical storage

yards, etc. It is made by filling highly expansive sodium-based bentonite between specially made composite geotextiles

and non-woven fabrics, and the bentonite anti-seepage pad formed by the needling method can form many small fiber

Spaces. The bentonite particles cannot flow in one direction. When they come into contact with water, they form a

uniform and high-density gel-like waterproof layer inside the pad, effectively preventing water leakage. Bentonite waterproof

blankets can be classified by production process into: needle-punched sodium-based bentonite waterproof blankets,

needle-punched film-coated sodium-based bentonite waterproof blankets, and adhesive sodium-based bentonite waterproof

blankets. The needle-punched coated sodium bentonite waterproof blanket is made by laminating a layer of high-density

polyethylene geomembrane on the outer surface of the nonwoven geotextile of the needle-punched sodium bentonite

waterproof blanket.

Performance features

Compactness - Sodium-based bentonite forms a high-density diaphragm under water pressure. When the thickness is about

3mm, its water permeability is below &×10 ⁻ 11m/sec, which is equivalent to 100 times the compactness of 30cm thick clay,

and it has a strong self-water retention performance.

It has excellent waterproof performance. As sodium-based bentonite is a natural inorganic material, it will not age or corrode even

after a long time or when the surrounding environment changes. Therefore, its waterproof performance is long-lasting.

Simple construction and short construction period - Compared with other waterproof materials, the construction is relatively simple

and does not require heating or pasting. Just connect and fix it with bentonite powder and nails, washers, etc. No special inspection

is required after construction. If any waterproofing defects are found, they are also easy to repair.

Not affected by temperature - it will not break brittle even in cold climates.

Integration - Integration of waterproof materials and objects: When sodium-based bentonite comes into contact with water, it has

an expansion capacity of 20 to 28 times. Even if the concrete structure experiences vibration and settlement, the bentonite within

the GCL can repair cracks on the concrete surface within 2mm.

Green and environmentally friendly - Bentonite is a natural inorganic material, which is harmless and non-toxic to the human body

and has no particular impact on the environment. It has excellent environmental protection performance.

It has a high performance-to-price ratio and a very wide range of applications. The product width can reach up to 6 meters, greatly

enhancing the construction efficiency.

Scope of application and application conditions: It is applicable to municipal (landfill), water conservancy, environmental protection,

artificial lake and underground waterproofing and anti-seepage projects of buildings.

It can still be applied at negative temperatures (-20℃) where traditional waterproof materials cannot be used. It can also be applied

on damp substrates (without standing water). Construction cannot be carried out in rainy or snowy weather. It is not suitable for

anti-seepage of strong acid or strong alkali solutions. As bentonite is an inorganic material, its durability is better than that of

organic waterproof materials.

Function and application

Waterproofing and seepage prevention in civil engineering (basements, green roofs)

Environmental protection project (landfill) anti-seepage and pollution control

Anti-seepage for water conservancy projects (artificial lakes, DAMS)