产品介绍:

![1602580445377220.jpg 201712270841308414[1].jpg](/static/upload/image/20201013/1602580445377220.jpg)

The Application of Composite Geomembrane in Channel Anti-seepage Engineering: In recent years,

the extensive application and remarkable achievements of geosynthetic materials in civil engineering, es-

pecially in flood control and emergency rescue projects, have drawn significant attention from engineering

and technical personnel. The state has put forward normative technical requirements for the application

technology of geosynthetic materials from aspects such as anti-seepage, reverse filtration, drainage, rein-

forcement and protection, which has greatly accelerated the pace of promotion and application of new

materials. This material has been widely applied in the anti-seepage projects of irrigation district channels.

Based on construction practice, this paper briefly discusses the application technology of composite geo-

membrane.

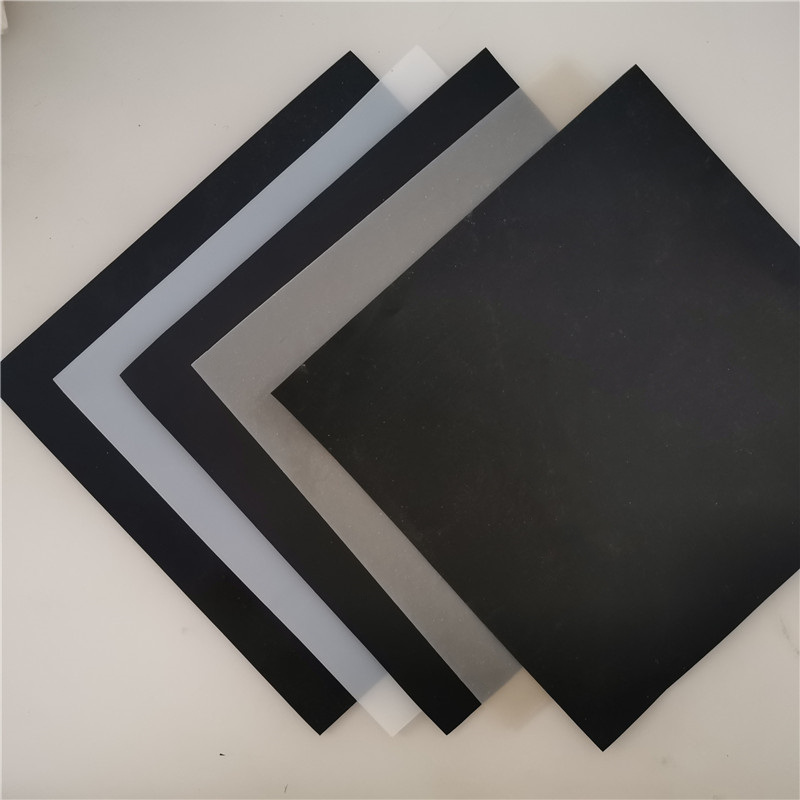

1. Performance of composite geomembrane

Composite geomembrane (composite anti-seepage membrane) is divided into one fabric and one

membrane and two fabrics and one membrane. It has a width of 4-6m and a weight of 200-1500g per square

meter. It has high physical and mechanical performance indicators such as tensile strength, tear resistance

and puncture resistance. The product features high strength, good elongation performance, large deformation

modulus, acid and alkali resistance, corrosion resistance, aging resistance and good anti-seepage performance.

It can meet the needs of civil engineering such as anti-seepage, isolation, reinforcement, and crack prevention

and reinforcement in water conservancy, municipal, construction, transportation, subway, tunnel, and engine-

ering construction. Because it is made of high molecular materials and anti-aging agents are added in the

production process, it can be used in unconventional temperature environments. It is often used for anti-seepage

treatment of DAMS and drainage channels, as well as anti-pollution treatment of waste sites.

2. Construction of composite geomembrane

Composite geomembrane is formed by attaching geotextile to one or both sides of the film. Its forms

include one fabric and one film, two fabrics and one film, two films and one fabric, etc. Geotextile, as the

protective layer of geomembrane, protects the anti-seepage layer from damage. To reduce ultraviolet rad-

iation and enhance anti-aging performance, it is best to lay it by the burial method.

During construction, the base surface should first be leveled with fine-grained sand or clay, and then the

geomembrane should be laid. Do not stretch the geomembrane too tightly. The parts buried in the soil at both

ends should be in a wavy shape. Finally, cover the laid geomembrane with a transition layer of about 10cm of

fine sand or clay. Build a 20-30cm layer of block stones (or concrete precast blocks) as a protective layer against

erosion. During construction, efforts should be made to avoid direct impact of stones on the geomembrane.

It is best to carry out the construction of the protective layer while laying the membrane. The connection between

the composite geomembrane and the surrounding structures should be anchored with expansion bolts and steel

plate pressure strips. The connection parts should be coated with emulsified asphalt (2mm thick) for bonding to

prevent leakage at this location. The seam treatment of composite geomembrane is a key process, which directly

affects the anti-seepage effect. The common joint methods include: ① Lap joint: The lap width should be greater

than 15cm; ② Hot welding: It is suitable for slightly thicker geomembrane base materials, and the lap width of

the weld seam should not be less than 5CM.(Adhesive bonding is not recommended. It is prone to delamination

after long-term water immersion and has poor anti-seepage effect.)

Years of practical experience have shown that the thickness of geomembrane should not be less than 0.25mm.

If it is too thin, air holes may occur and it is prone to damage during construction, thereby reducing the anti-seepage

effect. During the construction of geomembrane, special attention should be paid to ensuring that the laying is not

too tight, no wrinkles are allowed, and the splicing is firm. Construction must be carried out strictly in accordance

with technical specifications, and the five quality control points of preparation, laying, splicing, inspection and back-

filling must be well controlled. Due to the excellent anti-seepage effect of the composite geomembrane, it is widely

used in the water-saving renovation and follow-up supporting projects of the Baojixia Irrigation District at present,

and has received widespread praise from the design and construction units.