产品介绍:

![1602667354200127.jpg 1-20031Q04206[1].jpg](/static/upload/image/20201014/1602667354200127.jpg)

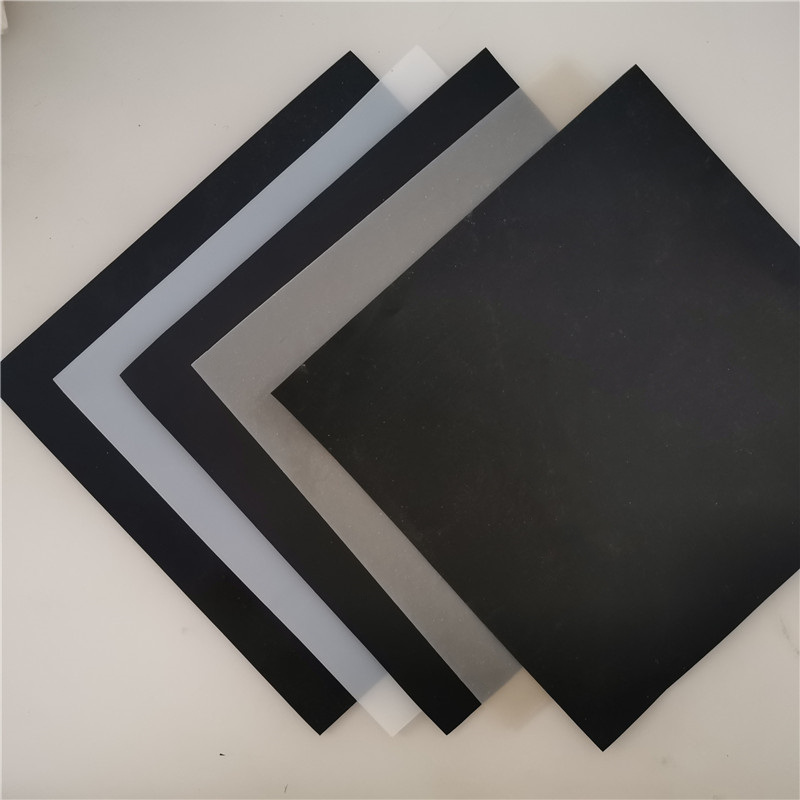

Introduction to Polypropylene Geotextile

Polypropylene geotextiles mainly include woven geotextiles, nonwoven geotextiles, geomembranes and composite

geotextiles. Among them, woven geotextiles are further classified into woven geotextiles and woven geotextiles.

Characteristics of polypropylene geotextile

All 1-polypropylene woven geotextiles are produced on wide shuttle looms or shuttleless looms such as shuttle and rapier looms.

Polypropylene woven geotextile is relatively suitable for the function of reinforcement and strengthening. Therefore, when

used for separation, reinforcement and control of corrosion, woven geotextile can generally be adopted.

2- Nonwoven polypropylene geotextile

Nonwoven geotextiles are generally produced on continuous production lines. Polypropylene nonwoven geotextiles are mainly

classified into two types according to the production process: spunbond method and short fiber needling method.

Production method of polypropylene geotextile

Spunbonding method

The particles or powder of the polymer are melted and then fed into an extruder, where they are spun into continuous long

filament bundles through one or a series of spinnerets. Then, by rotating the spinneret or controlling the airflow, changing

the speed of the conveyor belt, or applying current, the long filaments are irregularly arranged and laid on the conveyor belt

to form a fiber web. The bonding of fiber webs is carried out by hot pressing or bonding with adhesives, or mechanical

reinforcement with needling before the filaments have completely solidified, to form a continuous and uniform geotextile.

It can be used in various projects such as reinforcement, separation, filtration and drainage.

2- Short fiber needling method

Short fibers are carded into cotton webs by carding machines or waste cotton opening machines, and then cross-laid or directly

formed into cotton webs with randomly arranged fibers by air flow web-forming machines to achieve isotropy during fabric

formation. Then, through one or several groups of needle plates composed of a large number of needles, the fiber webs are

needled, causing the fibers to entangle and squeeze together to form nonwoven fabrics. This method is suitable for the production

of thick geotextiles, which are characterized by high density, loose structure, relatively thick thickness, good water absorption and

permeability, and strong resistance to deformation. They are particularly suitable for filtration and drainage projects.