产品介绍:

![1602751117120428.jpg 201910119313982398[1].jpg](/static/upload/image/20201015/1602751117120428.jpg)

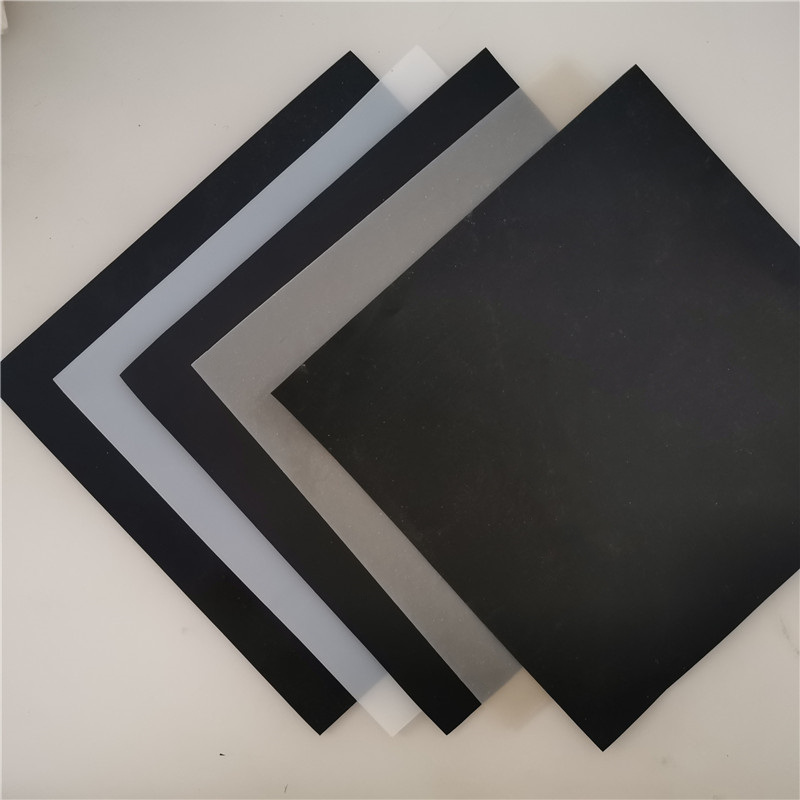

Rubber waterstop and waterstop rubber are mainly made of natural rubber and various synthetic

rubbers, with the addition of various additives and fillers. They are formed through plasticizing, mixing

and pressing. There are many varieties and specifications, including bridge type, mountain type, P type,

U type, Z type, B type, T type, H type, E type, Q type, etc. According to their usage, they can be further

classified into embedded rubber waterstop and back-attached rubber waterstop. This waterstop material

features excellent elasticity, wear resistance, aging resistance and tear resistance. It has strong adaptability

to deformation and good waterproof performance. The applicable temperature range is from -45℃ to +

60℃. Rubber waterstop must not be used when the temperature exceeds 70℃, or when it is subject to strong

oxidation or erosion by organic solvents such as oil.

The application scope of rubber waterstop

It is applied to the waterproofing of deformation joints in underground structures, DAMS, water storage

tanks, swimming pools, roofs and other building materials and structures.

Construction and installation of waterstop:

The waterstop is partially or fully embedded in the concrete during the concrete pouring process. There

are many sharp-edged stones and sharp steel bar ends in the concrete. Since the tear strength of plastic and

rubber is 3 to 5 times lower than the tensile strength, once the waterstop is punctured or torn, the crack will

expand without much external force. Therefore, during the positioning of the waterstop and the concrete

pouring process, Attention should be paid to the positioning method and pouring pressure to prevent the

waterstop from being punctured and affecting the waterstop effect. The specific precautions are as follows

The waterstop should not be exposed to the open air for a long time, protected from rain, and should not

come into contact with strong polluting chemical substances.

2. During transportation and construction, prevent machinery and steel bars from damaging the waterstop.

During the construction process, the waterstop must be reliably fixed to prevent displacement when pouring

concrete and ensure its correct position within the concrete.

4. The methods for fixing the waterstop include: fixing it with additional reinforcing bars; Special clamps for

fixation; When fixing lead wire and formwork, etc., if perforation is required, it can only be selected at the

edge installation area of the waterstop and must not damage other parts.

5. When placing an order, the user should calculate the product length based on the engineering structure

and design drawings. For special-shaped structures, there should be drawing explanations. It is advisable

connect the waterstop into a whole in the factory as much as possible. If on-site connection is required,

methods such as vulcanization bonding with an electric heating plate, cold bonding (for rubber waterstop),

or welding (for plastic waterstop) can be adopted. If the user has difficulty connecting, technicians can be

sent to provide on-site guidance.