详细内容:

![1602839109224845.jpg 1-2010131PJC39[1].jpg](/static/upload/image/20201016/1602839109224845.jpg)

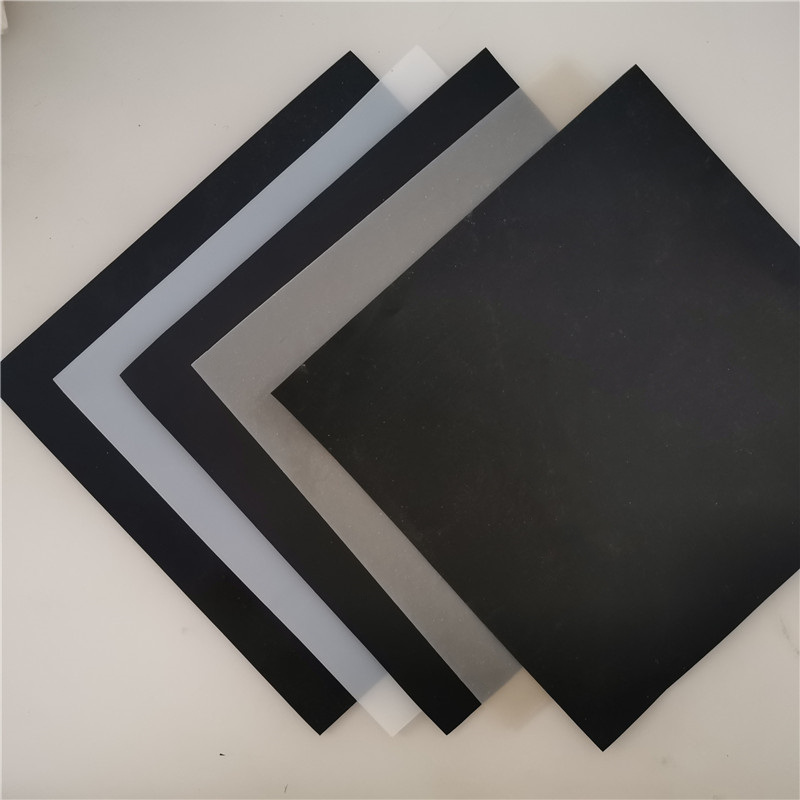

The causes of geomembrane breakage during engineering construction, based on the construction experience of various

projects, are actually influenced by the type of geomembrane, the thickness of the geomembrane, the temperature of the hot

wedge of the electric welding machine, the welding speed, the local climate temperature and wind force.

During the process of geomembrane splicing, it is necessary to avoid material leakage and leakage repair as much as possible

After on-site and indoor tests of welded parts, it was found that the fracture failure mainly occurred in the non-welded

areas close to the welded joints. Hot wedge welding machines are widely used in welding construction in China. On-site sampling

tests of many projects have shown that most of the fractures also occur in the non-welded parts at the edge of the weld seam,

to be precise, the parts close to the weld seam. This indicates that although the types and performances of welding machines

used at home and abroad are different, the welding parameters used are also different, and the climate conditions in different

places are not the same. The damage phenomena are basically the same. Through their respective research, different explana-

tions have been put forward for the causes of this phenomenon. Some people believe that it is caused by concentrated strain

at the joint edges, including abrasions at the joint edges. Some people believe that high welding temperatures have an impact

on the edges of the joints, including thinning in thickness and hardening of the material. The author believes that the high tem-

perature of the hot wedge will harden the edge of the joint, thereby increasing its strength. In fact, the upper and lower film

materials of the molten hot wedge may not strictly overlap. The tiny part outside the overlapping area will become a weak zone

where fracture occurs first, with a strength lower than that of the raw material, approximately 85% to 95% of the raw material.

However, although the fracture still occurs at the edge of the joint, the strength of the strictly overlapped joint is 5% to 15%

higher than that before welding, and the elongation decreases.

In fact, for a certain model of hot wedge welding machine and a certain model and thickness of geomembrane, the

selection of welding parameters such as hot wedge temperature, welding speed, and roller pressure is also affected by local

atmospheric temperature and wind force.

During the process of geosynthetic membrane splicing, it is necessary to avoid material leakage and leakage repair as

much as possible, especially during the welding process, to minimize missed welds and false welds, as well as multiple pause

points in a single weld seam. Although these defects can be repaired through inspection, the welding quality of handheld

welding torches is far inferior to that of welders.