产品介绍:

![1602750156428344.jpg 1-191201101P0[1].jpg](/static/upload/image/20201015/1602750156428344.jpg)

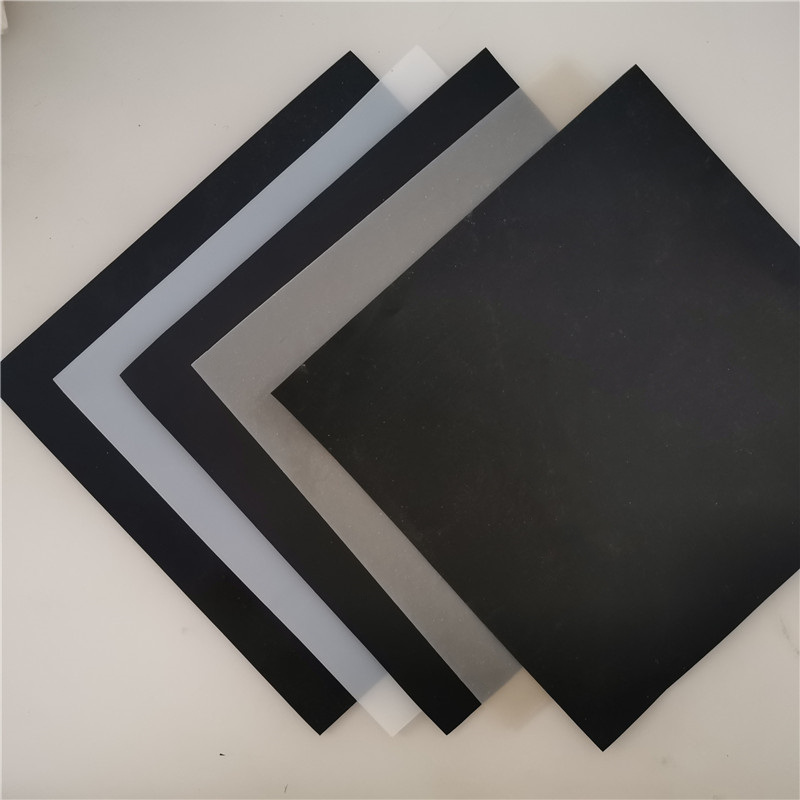

The back-attached rubber waterstop is mainly made of rubber and various synthetic rubbers as

the main raw materials, with various additives and fillers added. It is formed through plasticizing, mixing

and pressing. There are many varieties and specifications, including bridge type, mountain type, P type,

U type, Z type, B type, T type, H type, E type, Q type, etc. The back-attached rubber waterstop is mainly

made of rubber and various synthetic rubbers as the main raw materials, with various additives and fillers

added. It is formed through plasticizing, mixing and pressing. There are many varieties and specifications,

including bridge type, mountain type, P type, U type, Z type, B type, T type, H type, E type, Q type, etc.

Back-attached rubber waterstop can be further classified into embedded rubber waterstop and back-attached

rubber waterstop according to their usage.

The back-attached rubber waterstop is produced in accordance with the standard GB18173.2-2000 "Polymer

Waterproof Materials - Waterstop". Therefore, we can produce rubber waterstop of various shapes and sizes

according to the requirements of users. In addition, we also have cross-shaped, T-shaped, slope-shaped and

internal and external corner type products for the needs of different projects and different parts, which can be

applied to any design requirements. When transporting the waterstop products, direct sunlight should be avoided

and they should not come into contact with heat sources, oils or harmful solvents. Finished products should be

placed straight and flat, and no heavy pressure should be applied. The storage place should be maintained at

-10℃ to +30℃, with a relative humidity of 40% to 80%. The application scope of the back-attached rubber

waterstop: It is used for waterproofing of deformation joints in underground structures, DAMS, water storage

tanks, swimming pools, roofs and other building materials and structures.