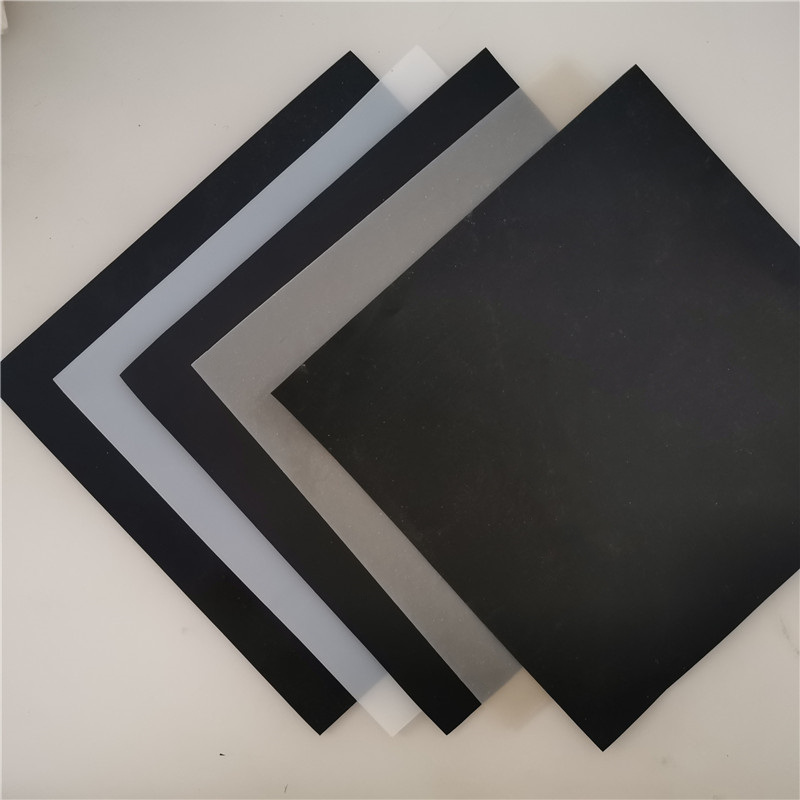

产品介绍:

Rubber waterstop and waterstop rubber series are mainly made of rubber and various synthetic rubbers, with

various additives and fillers added. They are formed through plasticizing, mixing and pressing. There are many

varieties and specifications, including bridge type, mountain type, P type, U type, Z type, B type, T type, H type, E type,

Q type, etc. It is made mainly from rubber or various synthetic rubbers, with the addition of multiple additives and

fillers, and processed through plasticizing, mixing, calendering and vulcanization. According to their usage, they can

be further classified into buried rubber waterstop and back-attached rubber waterstop. This waterstop material

features excellent elasticity, wear resistance, aging resistance and tear resistance. It has strong adaptability to deformation

and good waterproof performance. The applicable temperature range is from -45℃ to +60℃. When the temperature

exceeds 70℃ and the rubber waterstop is subjected to strong oxidation or erosion by organic solvents such as oil, it

must not be used. It is generally used in the construction of basement exterior walls and post-poured strips.

Rubber waterstop must be fixed with reliable measures when binding steel bars and setting up formwork. The

correct position of the waterstop in the concrete to prevent displacement during the pouring of concrete.Only holes

can be drilled at the permitted parts of the waterstop. When fixing the waterstop. The effective waterproof parts of

the waterstop must not be damaged.Common fixing methods include: fixing with additional reinforcing bars; Special

clamps for fixation; Fix it with lead wire and template, etc. No matter which fixing method is adopted, the fixing method

of the waterstop should be carried out in accordance with the construction specifications required by the design, and

the positioning of the waterstop must be accurate, without damaging the effective waterproof part of the waterstop,

and facilitating the pouring of concrete.