详细内容:

![1602839227864668.jpg 1-201012131919338[1].jpg](/static/upload/image/20201016/1602839227864668.jpg)

Cement concrete pavement plays a very important role in trunk road transportation due to its

high strength and good durability, which can withstand heavy traffic. However, during long-term use,

various diseases such as misalignment, cracking, corner fractures, subsidence and arching often occur,

resulting in poor road surface smoothness and bumpy driving, which seriously affects the normal use

function of the road. When maintenance funds are relatively tight and major repairs cannot be carried

out, laying an asphalt concrete structural layer on the old cement concrete pavement is a simple, effect-

ive and feasible repair measure. However, if the overlay is directly carried out, due to the temperature

shrinkage of the original cement concrete slab and the deformation under load, when the tensile stress

caused by the displacement of the old cement concrete slab exceeds the tensile strength of the asphalt

structural layer, the asphalt structural layer will naturally crack, and then be damaged under external

such as rain.

Problems to be noted when laying geotextiles

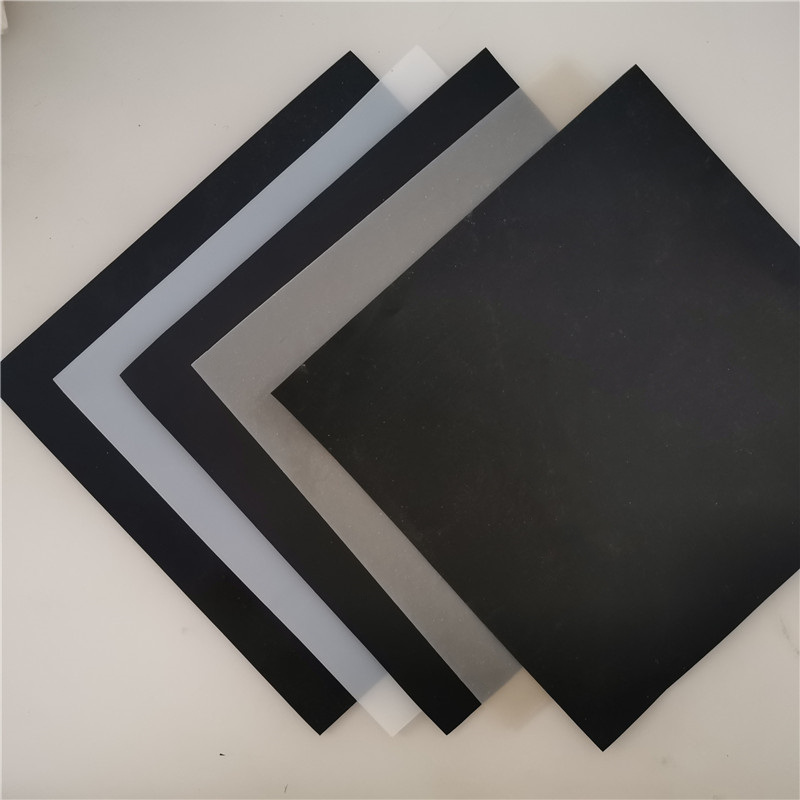

Before laying the asphalt structural layer, laying geotextile on the old cement concrete pavement can

effectively prevent the overlay layer from cracking. Due to the large deformation capacity and tensile

strength of geotextiles, the stress in concrete structures is absorbed and diffused, avoiding the phen-

omenon of stress concentration. The displacement of cracks in old cement concrete expands the stress

to a larger range through geotextiles. Geotextile soaked in asphalt oil is used as an insulation layer to

suppress the occurrence and development of temperature-type reflective cracks. In addition, as a water-

proof layer, geotextile soaked in asphalt binder can effectively prevent surface water from softening the

oundation and suppress the upward damage of capillary water in the foundation to the surface layer,

thereby reducing the peeling damage of the asphalt structural layer at reflective cracks. Practical exp

rience has shown that laying special geotextiles on old cement concrete pavements can effectively solve

problems such as cracks in cement concrete pavements and slow down reflective cracks in asphalt over

lay layers. Moreover, the cost of laying geotextiles is equivalent to that of laying a 1-centimeter-thick

layer of asphalt concrete. Therefore, the effect of laying geotextiles is obvious and it is worth promoting

widely.

When laying geotextiles, attention should be paid to: dealing with serious diseases of the old road surface;

Keep the old path smooth; Before laying, select ordinary asphalt as the bonding oil, heat it to 150-177℃, and

evenly spray it in the amount determined by the test (generally between 1.1kg/m ² and 1.6kg/m ²). The geotextile

should be laid flat without wrinkles, and the longitudinal lap width should not be less than 10 centimeters.