详细内容:

![1602839324108312.jpg 1-20093014555M39[1].jpg](/static/upload/image/20201016/1602839324108312.jpg)

Settlement of the base layer, leveling and chamfering of the ground - accurate measurement of specifications, retention of cutting sequence - laying of waterproof blankets for bank protection and riverbed - acceptance of construction projects - preparation of cement mortar or backfill soil protective layers.

Preparations before laying bentonite waterproof blankets

1. Grassroots solutions

(1) The key to the waterproof layer lies in the slope construction and bottom edge construction, which must be planned as a whole and continuously. Before laying the bentonite waterproof blanket, it is necessary to use the required machinery and equipment to level and compact the fine sand at the bottom. When large rock layers appear, unique solutions are required (depending on the compaction situation, remove or compact the large crushed stones), and fine sand should be filled in the large voids until the surface is smooth and the density reaches over 90%.

(2) The surface layer should be dry and rough, without obvious water marks or depressions. Bentonite waterproof blankets can be installed in damp and cold natural environments, but they should be prevented from being soaked in water.

(3) If the designed elevation at the bottom of the foundation soil layer is lower than the soil temperature, dewatering measures should be taken to drain the stored water.

(4) Compaction (or compaction and vibration intensity, etc.). It should be carried out after the base layer is leveled, and the relative density of compaction should exceed 90%.

(5) The construction of bentonite waterproof blanket should be carried out after the completion acceptance of the base applicable layer meets the standards.

2. Preparations before laying the bentonite waterproof blanket

(1) Conduct cutting analysis and draw the laying sequence and cutting diagram of the bentonite waterproof blanket.

(2) Inspect the appearance quality of the bentonite waterproof blanket, record any mechanical equipment damage, manufacturing trauma, perforation and other defects found, so as to facilitate maintenance during laying.

(3) The construction of the waterproof blanket should be carried out in a temperature without rain or snow. In case of rain or snow during construction, cover with plastic film to prevent the bentonite waterproof blanket from curing too early.

3. Lay the bentonite waterproof blanket

After basically meeting the requirements, the laying of the waterproof blanket is carried out in the order of the downstream reinforcing bars in the direction of water flow. First, slope protection (slope protection) is carried out, that is, the reinforcing bars of the upstream and downstream bentonite waterproof blankets overlap on the downstream bentonite waterproof blanket.

(2) Fit and level, with the lap length of the reinforcing bars being no less than 300mm.

(3) Evenly sprinkle 0.4 kg to 0.8 kg/m ³ of sodium-based bentonite powder or sodium-based bentonite balanced cement at the lap joint of the reinforcing bars.

(4) Considering the basic downward deformation, the bottom of the bentonite waterproof blanket can be wrinkled 1 to 2 times when necessary, with a wrinkling length of 100mm.

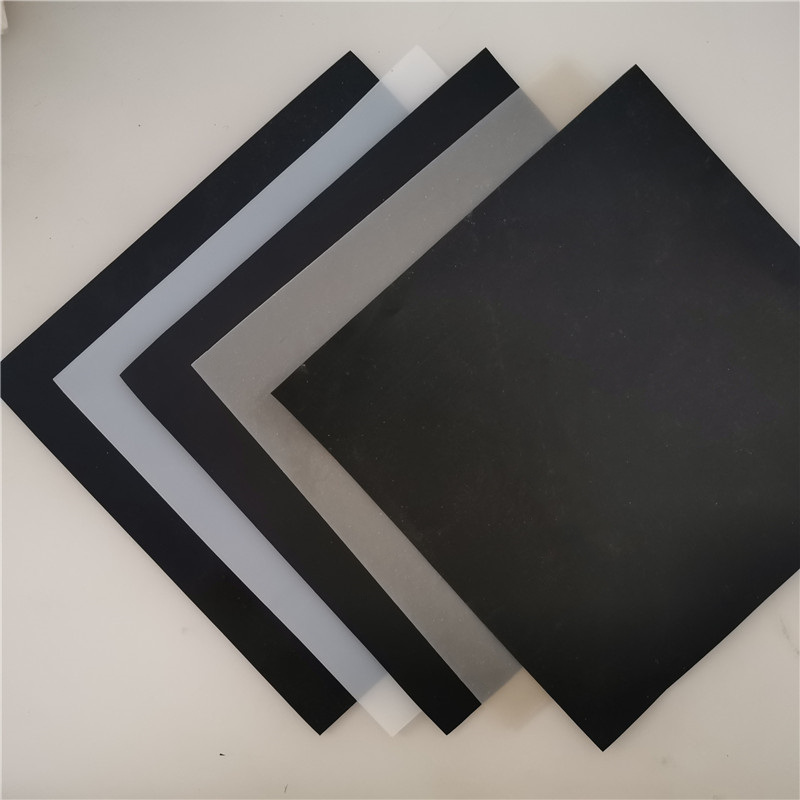

(5) Lay the bentonite waterproof blanket geotextile, that is, the milky white surface, and compact the top surface with 500mm thick plain soil. The slope protection is covered with bentonite waterproof blanket and compacted with water conservancy aerated blocks.

(6) If the bentonite waterproof blanket is damaged or has complex interfaces, cover it with a detailed bentonite waterproof blanket by adding a 300mm leg circumference according to the specifications of the damage or interface, and overlap a part of the double-layer bentonite waterproof blanket with sodium-based bentonite powder in the middle.

4. Construction of bentonite waterproof blanket for slope embankment

According to the specific conditions of the on-site construction, it is recommended to lay the waterproof blanket in a top-down sequence. For small-angle slopes, they can be immediately laid on the slope embankment and the protective layer should be completed as soon as possible. Slope protection should be made into arc-shaped or acute angles at the corners of the wall during construction. The waterproof blanket is best cut at the corner line with a total width of 400mm for hoisting and then laid in large quantities. When laying bentonite waterproof blankets on the vertical surface of the revetment, to prevent them from adhering firmly, they can be fixed with 25mm long nails and gaskets, or DIA prestressed immediate tensioning can be adopted.

5. A large amount of bentonite waterproof blanket was laid at the bottom of the river

For the laying of large-scale and large bundles of waterproof blankets, mechanical equipment should be selected. For the laying of small-scale and multiple bundles of waterproof blankets, manual services can also be chosen